--------> RESTORATIONS (click any image on this page to see larger version) Restoring an old Hamilton

|

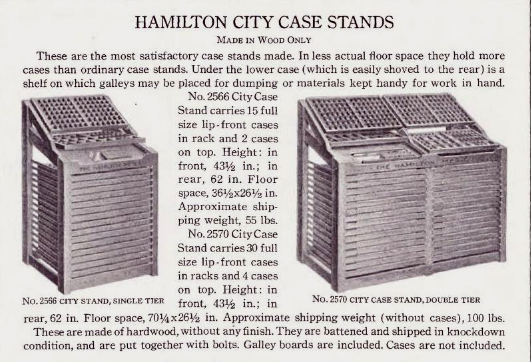

These are the side pieces of the Hamilton City Case Stand which we will be restoring. Note the extra details of the City Stand - the slots and runners. It is prepared to hold two cases firmly on the top as well as a "type bank" board beneath each of the cases. When there is no case in place - or when the lower case is slid up, forms and other items stored on the type bank can be accessed. A permanent shelf below the upper case can also be accessed after the case is put away. This is a convenient place to keep leads and slugs, etc... Note also that at the bottom, there is a cross-piece that does not quite match. This is part of a riser (repair?) that was added to this rack long ago - long ago enough that the soft wood used had many years to be damaged by moisture. We will replace this with risers made of Maple or another hard wood that will hold up well for the next 50-100 years. Hamilton used Elm. |

We've removed this side's risers

and have begun cleaning up and sanding the

remaining wood. We've removed this side's risers

and have begun cleaning up and sanding the

remaining wood. The wood is very dry and will benefit from a good dose of boiled linseed oil...  The new risers/base blocks will

be made of hard wood so that they last much longer

than the soft-wood patch that was attached many

years ago. The new risers/base blocks will

be made of hard wood so that they last much longer

than the soft-wood patch that was attached many

years ago. We measured the Stand and discovered that it is 4" lower than when it was new. That suggests that the bottom 4" were lost to water damage and these 4" risers were added to repair the cabinet - but that was a long, long time ago and the new soft-wood risers have also deteriorated and will be replaced. Hamilton shipped this stand to the ATF office in New York City - note the address stenciled on the side of the rack. An interesting note in dating this piece is that the General Offices of ATF had already been moved from Williams Street to Jersey City by 1906*. Unless, they continued to ship product from the Williams Street location, this City Stand may have been made - and shipped to ATF prior to 1906. - Hardly conclusive, but interesting... * ref Circuitous

Route.

|

Sat 5/11 -

Eureka! "I have found it!" - For

weeks, I have been searching for a nice, clean piece of

Poplar to use to complete the restoration of the Hamilton

City Type Case Rack for Kurt out in Ohio.... I went to

Lowes, Home Depot, Opdyke Lumber; I went on line looking

for a local source. I called Heacock Lumber - the mill

where I got my last lot of rough cut poplar - that I used

when we built the new workshop. No luck. I did order more

rough cut 2x6's, but they are being custom-cut and will be

far too green to use for anything important..

Eureka! "I have found it!" - For

weeks, I have been searching for a nice, clean piece of

Poplar to use to complete the restoration of the Hamilton

City Type Case Rack for Kurt out in Ohio.... I went to

Lowes, Home Depot, Opdyke Lumber; I went on line looking

for a local source. I called Heacock Lumber - the mill

where I got my last lot of rough cut poplar - that I used

when we built the new workshop. No luck. I did order more

rough cut 2x6's, but they are being custom-cut and will be

far too green to use for anything important..And then.... I walked into our local Hardware store - Frenchtown Home & Hardware - which has served our local community for many years as "the source" to find pretty much anything we might need related to hardware or home devices.... Well, when Mike took over from Gene, he also took over the space next door; the pharmacy moved into town and the hardware store doubled in size... and, over in one corner, Mike began displaying locally milled lumber - nice stuff - maple, walnut, etc.... AND some really, really nice, clean, straight, seasoned POPLAR! It cost me $40, but it is worth it. THIS is THE piece of wood I have been looking for. I could not be happier... and Kurt will also be happy to get his restored circa 1900 Hamilton City Case Stand...

August 9 -

Well,

now that the tractor and

web server issues are behind

us, we can finally get back to working on

this classic Hamilton City Stand.

Well,

now that the tractor and

web server issues are behind

us, we can finally get back to working on

this classic Hamilton City Stand. We have assembled the pieces - all except the long bolts which "are around here somewhere". I'll find them.

So far, I a have cut the new Poplar risers - and believe me, cutting precise "L" shapes from a thick piece of Poplar is a bit tricky! In the photo to the right, I am drilling the first one to match the bolt hole of the old upright.

Next, we'll remove it and run it through the thickness planer until it fits perfectly next to the 100-year old legs of this old classic, then we'll cut a mortise for the crosspiece, drill it for the embedded bolt, and attach it to the main frame. Later, when it arrives in Ohio, assembly will be simple, with all pieces pre-fitted. We are also beginning to feed this 100-year-old dried wood with some brushed-on Linseed oil. This repair will last another 50+ years...

Saturday,

August 10

Saturday,

August 10 Well, today, we finished milling, fitting and mounting the risers. We also sorted through all of the upper front and rear crosspieces and found the two - the only two out of the multiple sets that we have - that fit perfectly; these are the ones that were made for this frame 100 years ago...

So this is the "First Fitting". We still need to fabricate the front and rear lower cross pieces - and mortise them into the risers.

click on the photo for a close-up view

---->>>

And, we need to make the front-rear braces as well. They

will likely mount to the inside of the risers with a

1/2-mortise We'll figure that out tomorrow... And then

we'll continue the sanding of rough spots and oiling of

the entire frame. The sanding will get rid of splinters

and dings acquired over the years and the oil will bring

this dry, 100-year old wood back to life...We did find the long bolts, btw... the original carriage bolts that held the risers on so many years ago. But carriage bolts rely on firm, fresh wood to hold still as the nuts are tightened. I wanted to keep the old, patina'd bolts rather than use shiny new hex head 6" bolts. The the round-head carriage bolts are no good to re-use on old wood, and, rather than press into and grip the wood as they did 50+ years ago, they just spun when we tightened the nuts... So, to get a grip on the head, we ground down two sides of the round head, making two flat sides that could be gripped using a 9/16" open end wrench.

And then we turned the bolts on the lathe to round off the square shank at the end - beneath the head. We wanted to fit washers beneath the head, but carriage bolts are squared on the inside to grip fresh wood. And now, that square got in the way, so we turned them off and made them round - to fit the washer. When the bolts were ready, we installed them with washers on both sides and used the open end wrench to hold the carriage bolt head from turning as the nut is run in on the other end. It is nice and tight. And, it looks more original this way....

Monday, August 12 Getting all of the pieces

together...

Monday, August 12 Getting all of the pieces

together... These are the pieces to finish the job. The rough-cut Poplar will be milled to thickness, then cut to make front, rear and side pieces with joining tenons on both ends.

Milling the wood and Mortise & Tenon - We cut our rough cut Poplar 2x6 into lengths for the lower front, rear and side pieces. The old pieces that were on this unit were not re-usable, so we are making new pieces to replace them.

First, we had to

mill the Poplar down from 2" to 1.25" using our Thickness

Planer. It took some time, but was worth the effort. Soon

we had the wood to the desired thickness. Then we ripped

each of the two pieces in half to make 2 identical side

braces and two identical lower front and rear braces.

First, we had to

mill the Poplar down from 2" to 1.25" using our Thickness

Planer. It took some time, but was worth the effort. Soon

we had the wood to the desired thickness. Then we ripped

each of the two pieces in half to make 2 identical side

braces and two identical lower front and rear braces. We cut the tenons on our Hammond Glider Trim Saw - a saw so precise, the you can trim to within 1/2 of a point. But today, we were just hogging off a lot of wood to make the tenons.

By adjusting the blade to just the right height, we cut .5" tenons that will fit snugly into the .50" mortises we will drill on the drill press.

Next, we drilled our first mortise and, as you can see, it came out well and

resulted in a perfect fit of

our test pieces.

resulted in a perfect fit of

our test pieces.

Now we have to remove and mortise the risers to accept the new tenon'ed cross pieces.

...getting a bit closer every day.

Friday, Aug 17

Friday, Aug 17It's got feet! Yes. The side rails are done, mortised and tenon'd and fit back into the sides of the stand to check their fit. It's perfect! Now the stand reaches its full original height. And, these feet that we call "risers" are made of custom-milled Poplar that will last at least another fifty years.

Next, we will drill 4 more mortises into the risers - plus holes for the hidden bolts that will hold this all together. The we'll fit the tenon'd front and rear lower cross pieces into their respective mortises for nice, solid joints, and we will have put the whole thing together! held in place by 6" hidden bolts - just like from the factory over a hundred years ago... This thing is solid!

Tuesday, Aug 26

Tuesday, Aug 26Finally. After far too long - and after a recent press move followed the flood, this 125-year-old Hamilton City Stand Open Frame Type Case Rack is all together.... All that's needed now are some shelf boards for the top, some long bolts to hold it tightly together, one set of replacement rails for the top slots, and some finishing.

I will stain the new pieces to make them less obvious, sand any remaining splinters and rough spots on the old frame, then oil everything to bring the old, dry wood back to life and to protect it during it's next 100 years.

The 8 mortise & tenon joints, backed up by 6" long deep bolts will assure that it stays tight and square and can handle the weight of 15 type cases full of metal type, plus what ever winds up on the sloping work top.

Tuesday,

Sep 10

Tuesday,

Sep 10Well, more days have passed and the stand is not ready to ship yet. But it is together and everything fits and works as it should. In the photo to the right, you can see the bright blond poplar parts standing out in contrast with the 100+ year-old aged wood. We found a special stain at Home Depot today that claims to put an "aged" finish on fresh wood. We'll try that out tomorrow and see how well it works to make this two-tone piece one single, boring tone...

The two new case slide rails are made and installed. They are not, btw, meant to hold a type case. Instead, they hold a large type-case-sized board that can be used for materials storage. A photo from behind will show that better. I'll post it as soon as I get a chance. I've also milled some of the poplar to fit into the side rails as galley boards. This City Stand is the premier of the open-frame type case racks. It includes one flat storage board as well as two more sloping storage areas - "galley boards" - that can be used to hold galleys of type, spacing, engraivings, ornaments, borders, sorts - what ever. Lots of extra - and handy - storage in this stand.

The Stand now has two new lower cross rails. I made a dumb mistake while cleaning up the first set I had made - the ones shown in the photo above... In "cleaning up" the tenon joints, I trimmed off just a bit too much of the cross-piece length. Everything looked and fit beautifully, but when I tried to slide a case in.. damn! It was 1/8" too tight. No good. I had to make two new lower rails... Not quite "back to the drawing board", but certainly "back to the Hammond Saw", indeed.

And, more than

that, each cross rail needs to have a 5" deep hole drilled

in from the end for the assembly nut and bolt. Drilling a

5" deep hole perfectly centered and parallel to the length

with a hand drill proved difficult, so I removed the tail

stock from my metal lathe, made a "sled" to hold the rail,

inserted a 5/16" drill bit in the lathe chuck and made my

own sort-of-horizontal-drill press, sliding the rail along

the sled and over the drill bit. In any case, it worked

and I got the holes drilled down the center.

And, more than

that, each cross rail needs to have a 5" deep hole drilled

in from the end for the assembly nut and bolt. Drilling a

5" deep hole perfectly centered and parallel to the length

with a hand drill proved difficult, so I removed the tail

stock from my metal lathe, made a "sled" to hold the rail,

inserted a 5/16" drill bit in the lathe chuck and made my

own sort-of-horizontal-drill press, sliding the rail along

the sled and over the drill bit. In any case, it worked

and I got the holes drilled down the center. So. Some more photos. A little more sanding of rough edges, and then this tricky new stain to make the new wood look old. Let's see how well it works. And then, I can strap it the skid that's waiting for it outside the door, build a protective box around it and get it on the way to its new home.

Sunday, September 15

Finally got the last of the sloping shelf inserts done - one of which has a nice little lip attached to hold the galleys from sliding off the edge. It's fastened in place using fluted dowels rather than a couple of finishing nails that might come loose in 10-20 years. These pegs will hold the lip in place for the next fifty years... I also added a removable cross-piece to help support any type case set on the upper shelf. Now all of the wood is cut and planed and fit and ready to be stained.

I also came up with a neat trick to make it easier to fit the square nuts that hold the cross-pieces in place. I'll be adding photos to show how I did what I did and why...

The special new stain I found - an "Aging Accelerator" stain - is working well to blend the fresh blond Poplar with the now 100+ year-old untreated wood that Hamilton used when they built this piece over 100 years ago.

So. No photos tonight - just a quick text update. I'll be back with photos soon...

page last updated September, 2019